22.05.2025

Commentary

While timing may have changed—EUBR requirements have not

Assuming and anticipating that this proposal is accepted by the European Parliament and the Council, the new deadline to fulfil and verify the due diligence requirements will shift from August 2025 to August 2027, and the Commission will provide final guidance in July 2026. This gives European Member States time to establish third-party notified bodies and economic operators time to ensure their batteries comply.

It’s important to be clear that the core requirements of the EUBR and its due diligence obligations (Chapter VII) are not changing—the timeline is simply shifting.

The EU Batteries Regulation, as already enacted into force in August 2023, still requires:

- A risk-based approach to identify and address adverse impacts in critical mineral supply chains, as directed by the OECD.

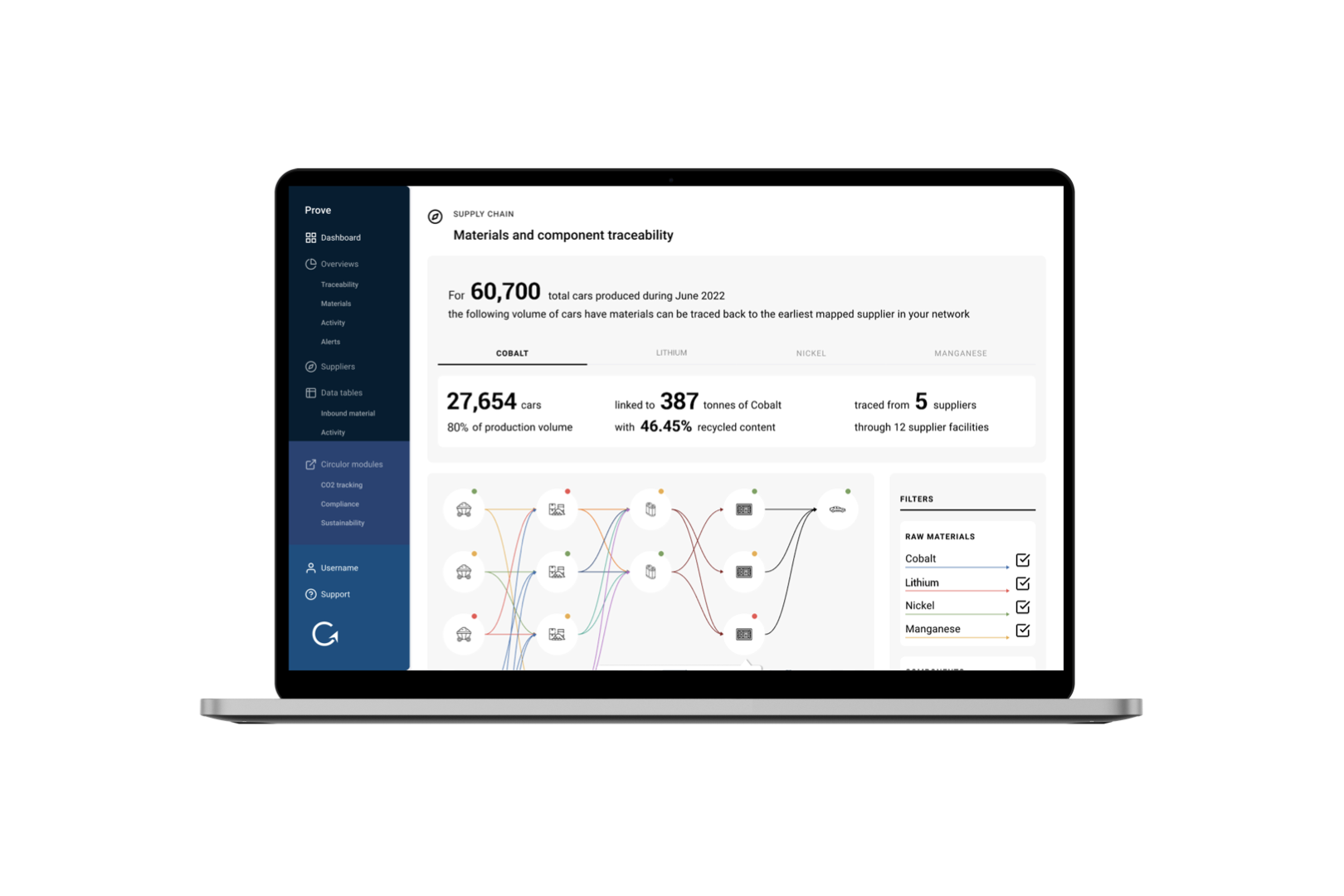

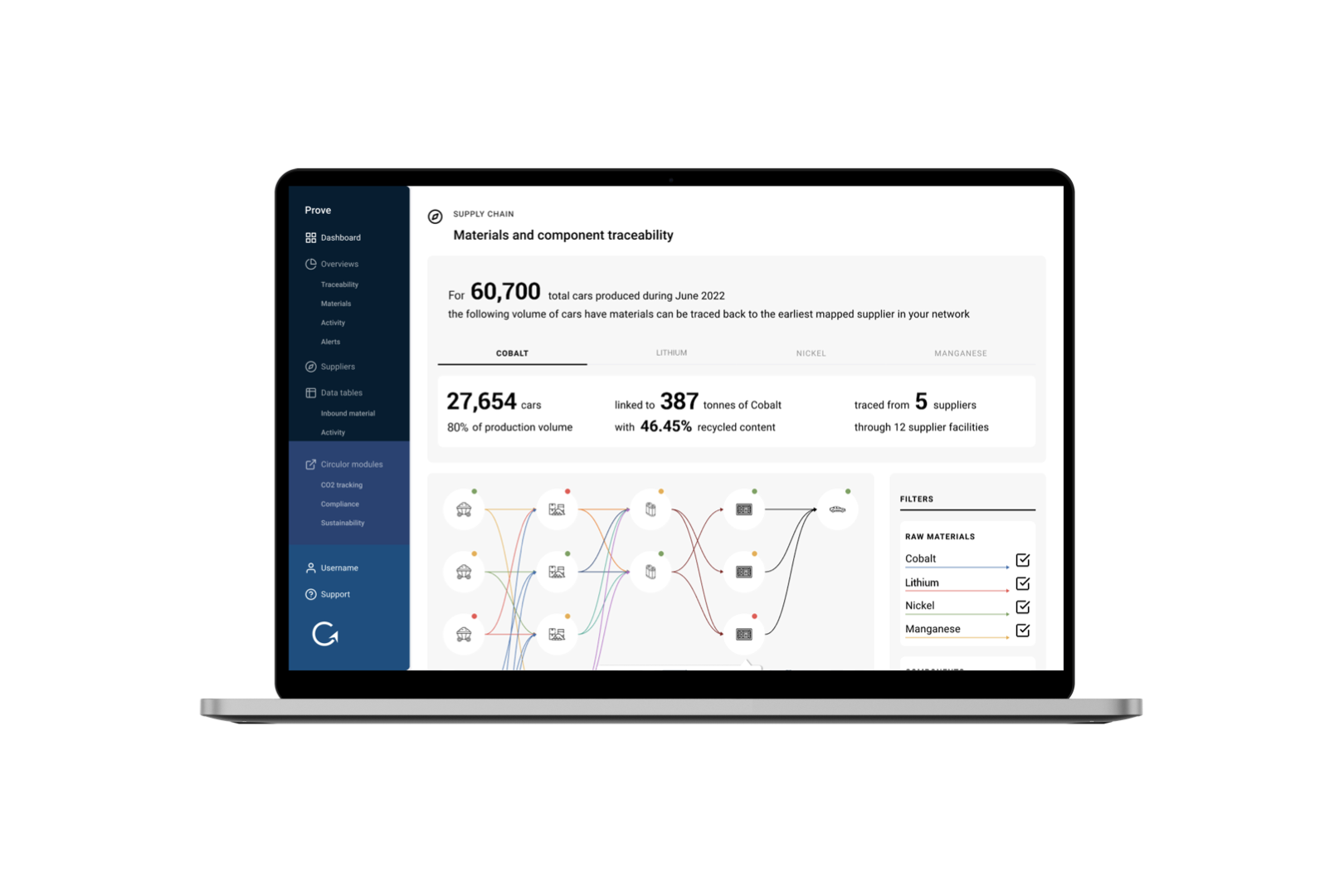

- A system of controls and transparency, including chain of custody and traceability for primary and secondary cobalt, lithium, nickel and natural graphite—from provenance to product.

- A digital battery passport for batteries placed on the European market by February 2027.

Companies shouldn’t see these additional two years as something to squander. As the Commission highlights in its proposals, it takes time to analyze and adjust supply chains, and digitalization remains a critical commitment of theirs to uphold high standards of operations and products, while streamlining and accelerating effective reporting for both companies and authorities.

So, use your time now wisely now.

- Get intimately familiar with the OECD due diligence guidelines, on which the EUBR Due Diligence requirements are based.

- Map your supply chains and complete initial risk scoping to prioritize suppliers.

- Establish chain of custody controls with material traceability. In doing so, you will maximize the effectiveness of your supply chain mapping efforts by dovetailing straight into the data collection of the actual flow of upstream materials.

- Conduct progressively in-depth due diligence based on what you’re seeing in the upstream.

In the spirit of European and business competitiveness, we must remember that supply chain transparency and resilience is core to mitigating risks and improving economic strength.

The ability to differentiate suppliers and products based on high standards is a competitive advantage for Europe, especially when pursuing reindustrialization and investment in batteries and critical minerals. The EUBR and OECD Guidelines have already prompted other markets to follow suit, so whether for this policy or a growing number of others, as well as financial and business obligations, the time to start is now.