12.12.2024

Press Releases

Circulor and Cyclic Materials Pioneer End-to-End Traceability of Rare Earth Elements

LONDON, December 12, 2024 – Cyclic Materials, the advanced recycling company for rare earth elements (REEs), and Circulor, the leading supply chain traceability solution, are collaborating to implement the world’s first end-to-end traceability of REEs.

REEs like neodymium, praseodymium, dysprosium, and terbium are essential components in critical technologies, from electric vehicles and wind turbines to consumer electronics. With global demand for REEs expected to triple by 2030 and supply chains heavily reliant on mining dominated by China, recycling these materials is a vital solution for resilience and sustainability. And thanks to Cyclic Material’s pioneering innovations, recovering REEs efficiently can now be achieved.

This partnership sets a new standard for transparent REE recycling that signals a shift toward more responsible, sustainable, and secure sourcing of these materials. It provides automotive, renewable energy, and consumer electronics industries with verifiable proof that the recycled mixed rare earth oxides (MREOs) they receive from Cyclic Materials are produced at high standards, enabling them to differentiate their products on the global market.

Traceability is a critical piece of scaling critical metals recycling technologies, including rare earth, cobalt and copper. Given the environmental and human rights challenges associated with some of the mined critical metals, traceability ensures accountability in our production supply chain, builds trust across the value chain, empowers industries to meet sustainability goals without compromising performance or innovation, and above all helps the customers to make the right choices in developing their purchasing strategies. Our partnership with Circulor is the concrete proof of our commitment towards establishing a scalable trusted circular economy for critical materials.

Ahmad Ghahreman, CEO Cyclic Materials

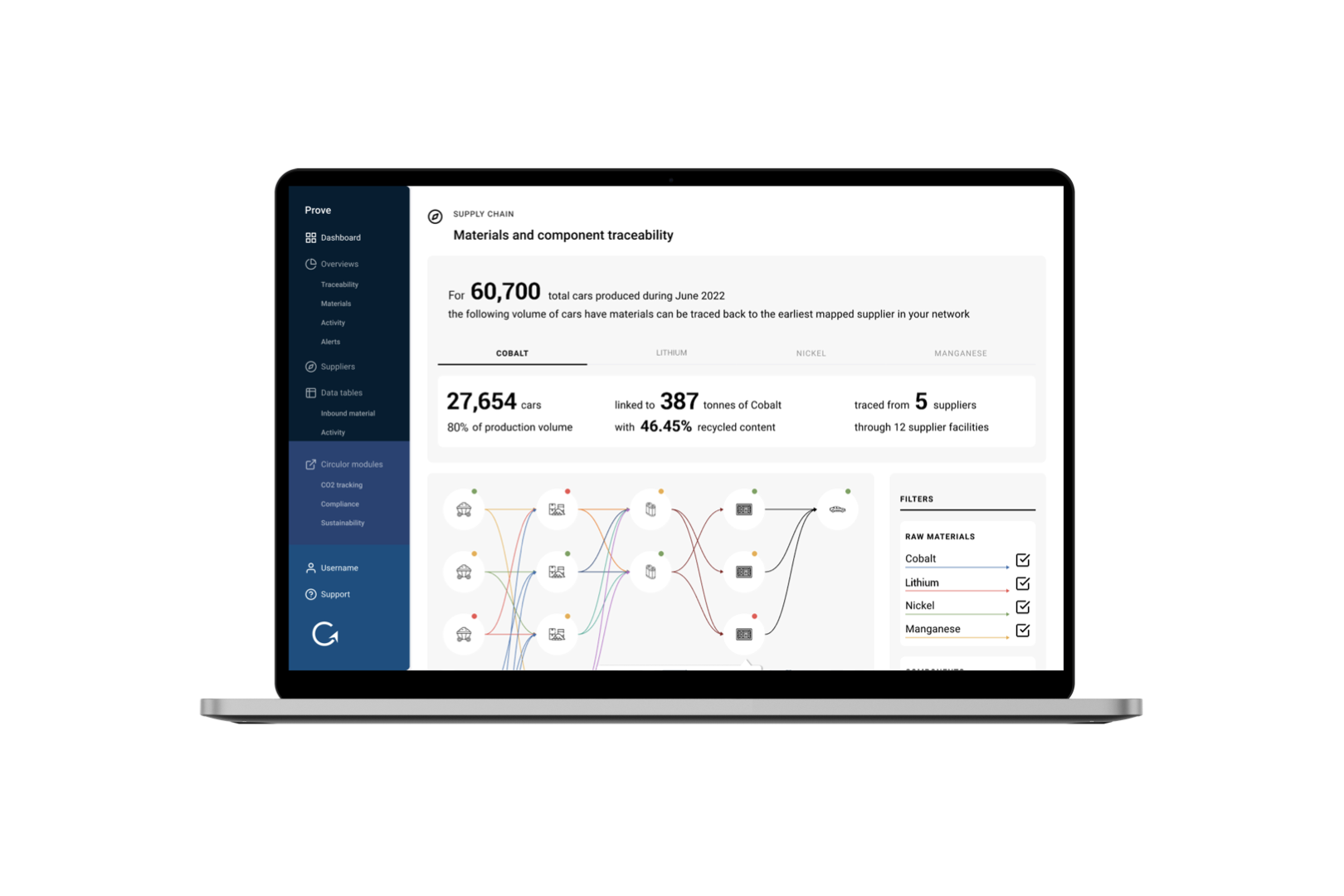

Through Circulor’s PROVE platform, the project collates granular production, traceability, and carbon emissions data from Cyclic Materials’ facilities in Kingston, Ontario, to create a digital product passport (DPP) for Cyclic Materials recycled MREOs that provides proof of recycled content specifics and the origin of the material. Together, they sequentially collate data from subsequent facilities planned across North America and Europe.

We’re proud to work with Cyclic Materials to establish first-of-its-kind traceability for recycled rare earth elements (REEs) — essential for clean energy, electronics, and critical infrastructure. As demand for REEs soars, recycling offers a sustainable, secure alternative to traditional sourcing, which Circulor’s digital product passports will verify.

Douglas Johnson‑Poensgen, CEO Circulor

Increasingly, REE recycling is also important for economic security and compliance with global regulations, including Europe’s Critical Raw Materials Act (CRMA) and the End of Life Vehicle Regulation Proposal (VRP) which have stringent targets for sustainable material sourcing and circularity.

But this is bigger than complying with labelling and circularity regulatory requirements. Establishing an immutable and reliable digital chain of custody for MREOs brings credibility to the recycling industry and streamlines the use of local recycled content that is competitive on a global scale.

![Acculon RA Circulor - website image.001[44].png](/_next/image?url=https%3A%2F%2Fdecisive-wonder-fa24533282.media.strapiapp.com%2FAcculon_RA_Circulor_website_image_001_44_2720fb315d.png&w=1920&q=75)