08.06.2023

Commentary

The importance of Material Traceability data in meeting the EU Battery Regulation

The EU Battery Regulation aims to minimize the negative impact of batteries on the environment, promote their efficient use and recycling, and safeguard consumer interests in an increasingly digital and electrified economy. In this pursuit, the regulation outlines due diligence obligations for economic operators and supply chain participants to create a more sustainable, responsible, and circular battery value chain.

From 24 months after enactment, article 49 of the regulation requires economic operators to “establish and operate a system of controls and transparency over the value chain, including a chain of custody or traceability system", for cobalt, natural graphite, lithium, and nickel supply chains.

This enables companies to:

- Create transparency and accountability: Every step in the supply chain process is to be monitored to identify the ongoing status of issues, such as illegal labor practices, poor environmental standards, and conflict minerals. The regulation requires economic operators to identify the upstream actors in their supply chains and build transparency by creating mechanisms for ongoing two-way communication between supply chain participants and their business operations.

- Prove responsible sourcing and supply chains: The mining of certain raw materials can be associated with human rights abuses and therefore requires economic operators and their supply chain participants to demonstrate compliance with due diligence policies, including the Conflict Minerals Regulation and OECD Due Diligence practices. Traceability systems support this by collating and providing the data needed to comply with these due diligence policies and conformity assessments on a continuous basis.

- Reduce environmental impact: Carbon-intensive production and potential ecological degradation are a concern for the batteries industry, and, therefore, the regulation requires that each battery disclose its embedded carbon emissions by 2025. As economic operators are responsible for the upstream activities that produce their batteries, traceability enables companies to verify whether their suppliers are adhering to environmental standards, identify hot spots of emissions, and engage with suppliers as needed to improve ESG performance.

- Support the growth of a circular battery economy: Batteries placed on the EU market are to disclose their amount of recycled content by 2028 and meet certain thresholds by 2031. With complete material traceability, end-of-life batteries can be efficiently recycled, and their material fed into next-generation batteries. This ensures valuable minerals are recovered and reused, and economic operators are building streams of recycled feedstock to hit future targets.

- Boost consumer confidence: The traceability of battery materials provides consumers with insights into upstream production activity. In turn, this data can be used to create a “digital product passport”—or digital identifier—which is required for batteries in the European market from 2027 onwards. In creating this consumer transparency, economic operators and original equipment manufacturers can unlock greater margins and new market

How Circulor Can Help

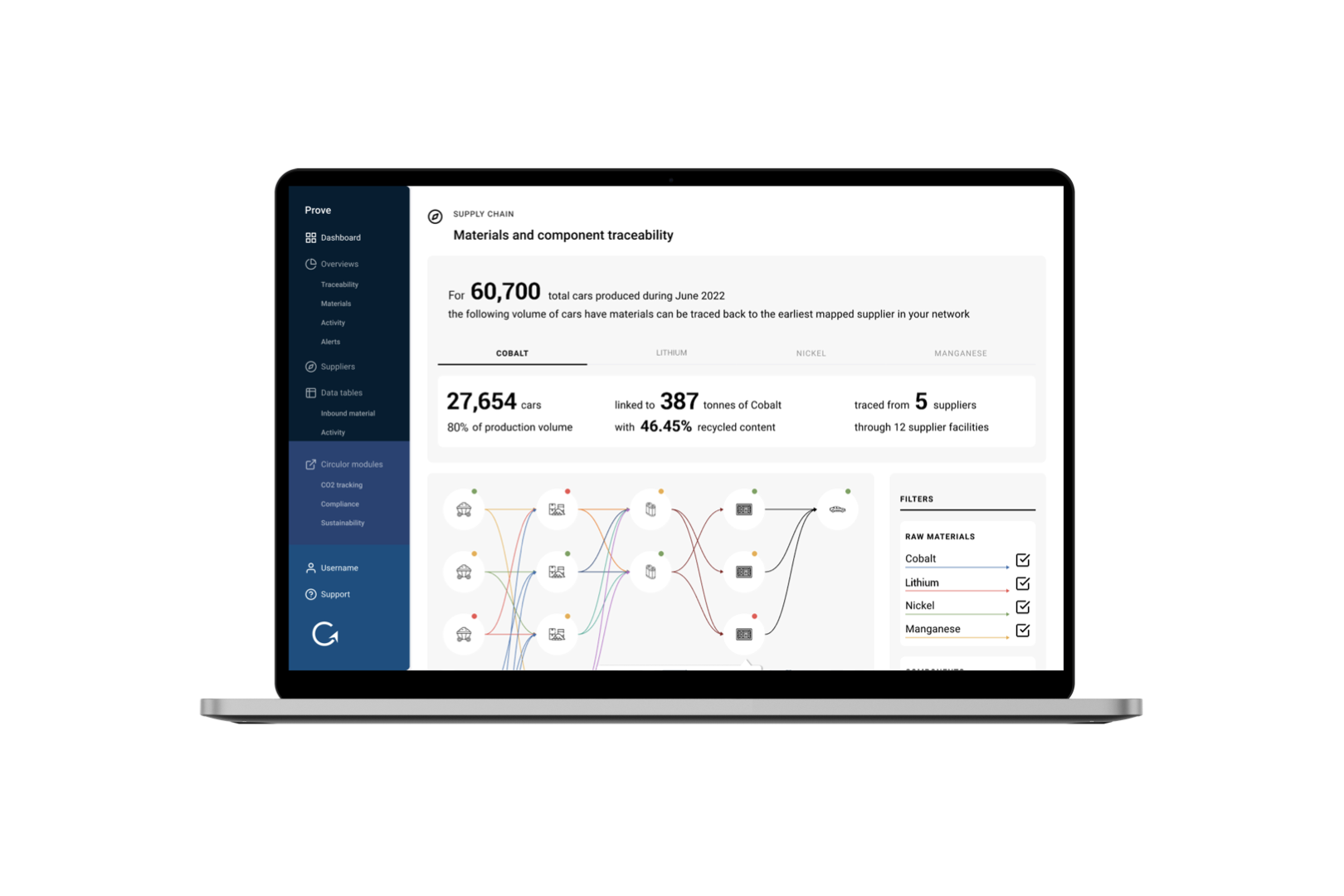

Circulor’s pioneering approach to supply chain visibility, at the item level, enables companies to enact a system for fulfilling the requirements of the EU Battery Regulation, including due diligence, carbon footprint, recycled content, and digital battery passports for batteries placed on the marketplace or into service.

Beyond compliance, customers also reap the benefits of reduced uncertainties and risks, greater supply chain resilience, and increased competitive advantage, especially in regard to driving faster pathways to circular economies.

- Trust in a material’s origin and production flow: Circulor’s technology platform which uses a combination of technologies to track the flow of materials, including blockchain, creates an immutable record of each unit of material, tracking it through the supply chain even as it changes state. This lets downstream companies know the provenance, journey, and activity incurred by the material along the way.

- Gain visibility of supply chains: Comprehensive visibility into the supply chain allows companies to identify supply chain risks and vulnerabilities, such as a supplier that isn't meeting its requirements or a geographical region that's subject to political instability. With this information, companies can make informed decisions to mitigate risks and enhance supply chain resilience. Circulor’s supply chain traceability solution identifies upstream actors, and monitors and tracks critical raw materials and components throughout the battery value chain, from extraction to the end of a product’s first life and beyond.

- Analyze supply chains more thoroughly: Circulor collates and analyzes supply chain data, allowing companies to measure the performance of the supply chain and efficiency of materials and operations. This enables them to identify patterns, risks, and opportunities that might be missed otherwise. This not only helps meet regulatory requirements, but also contributes to more efficient and cost-effective operations.

- Know products at a deeper level: Circulor’s digital battery passport, underpinned by proven supply chain traceability, provides a secure and verifiable record of a battery’s origins, components, and the production processes across the supply chain. Providing consumers and businesses with a clear understanding of what a product is made of and how it was produced, motivates responsible consumption and sustainable production, while improving the competitiveness of European products.

- Achieve a circular battery economy: By ensuring efficient tracking and tracing of materials, Circulor's solutions can support the transition to a circular economy by creating higher transparency on material value and potential circularity of products, for instance, item repair history, material composition for safe dismantling, and the levels of specific recycled content. In turn, this can aid in resource recovery and efficient recycling.

In summary, the traceability requirements of the EU Battery Regulation, which become increasingly stringent over time, require granular, harmonized traceability data across the value chain to ensure the sustainable and responsible production of batteries.

Tools like Circulor support companies in fulfilling these requirements and digitalizing their ways of working, in order to improve their supply chain resilience and contribute to a sustainable circular battery economy.

![Acculon RA Circulor - website image.001[44].png](/_next/image?url=https%3A%2F%2Fdecisive-wonder-fa24533282.media.strapiapp.com%2FAcculon_RA_Circulor_website_image_001_44_2720fb315d.png&w=1920&q=75)