03.09.2024

Commentary

Why a neutral third-party is essential for supply chain transparency

Across value chains, businesses need end-to-end traceability to prove their commitment to responsible sourcing, reduce carbon emissions, manage supply chain risks and meet consumer demands for sustainable products.

Regulatory requirements such as Europe’s Battery Regulation and Ecodesign for Sustainable Products Regulation (ESPR), and the U.S.’s Clean Vehicle Tax Credit, demand robust traceability and digital product passports (DPPs) – with deadlines fast approaching.

Whilst global manufacturing organizations possess the technological capabilities, the reality of looming deadlines and the investments of time, money, and resources needed to build an in-house solution make it impractical, especially when expertise is being diverted away from the core business. Conversely, asking companies to ‘mark their own homework’, as some critics have aptly put it, carries a multitude of risks.

Therefore, as businesses navigate the dilemma of building an in-house traceability solution or working with an independent expert, the importance of neutrality cannot be overlooked.

Collaborating with Circulor provides neutral and verifiable assurance of supply chain transparency

Independence and objectivity:

Proving sustainability and responsibility in complex supply chains necessitates an independent, neutral actor.

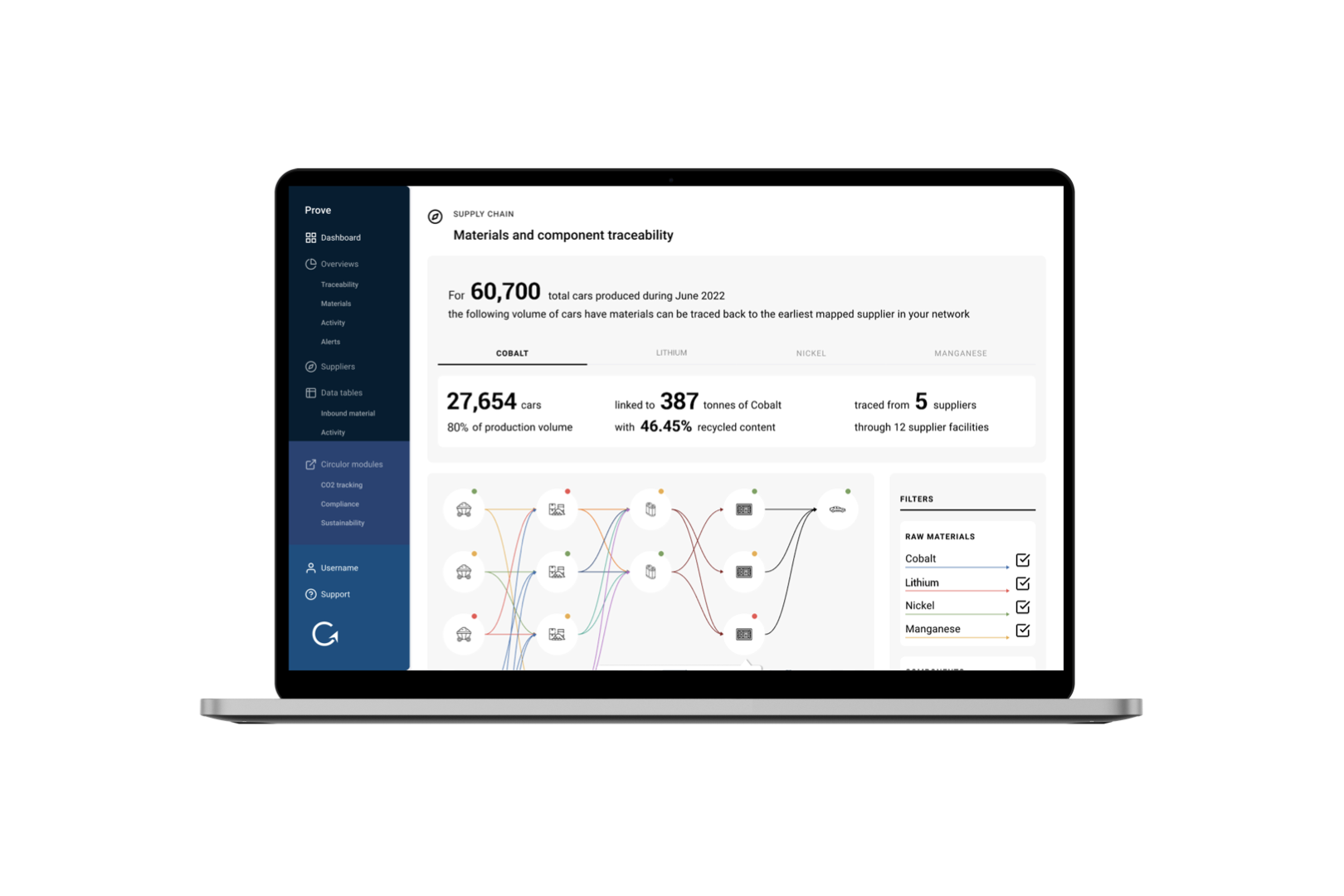

Circulor is an impartial, independent, and agnostic solution provider that processes data from multiple organisations such that it can be verified and audited with confidence by all. This provides the assurance needed for informed decision-making, ultimately accelerating the pathway to more responsible and sustainable business practices.

As policymakers seek to make sustainable products the norm through the ESPR, they recognise the enabling role of third-party traceability and DPP providers.

Not only do they state DPPs can be managed and stored by a third-party product passport provider, but they also require economic operators (those responsible for producing a DPP when placing their product on the market) to back up their DPPs through a certified independent third-party product passport service provider.

Data security and sharing:

As a technology partner to many large OEMs and supply chain participants, Circulor ensures that it does not request or store any sensitive information and only collects data relevant to the products that are being tracked.

Circulor is committed to looking after that data securely and responsibly. Even though the data is on the Circulor platform, it is not visible to all other users and is locked securely. Using unique identifiers at the predefined data collection points across a supply chain, Circulor ensures only the network participant with the correct “key” is permitted to see certain data.

Only a neutral-third party can assemble and manage this kind of tailored and secure access.

Cross-industry collaboration and standardization:

Circulor has been actively engaged with Catena-X, Global Battery Alliance, and SAE International’s battery passport committees since each was established.

As the technology lead of the German “Battery Pass” project, Circulor is at the forefront of the product passport definition and implementation, as well as the practical delivery of both upstream traceability for primary data and the maintenance of battery passports for circularity.

In addition, we have a full ecosystem of relevant advisory, audit, delivery and channel partners, including Deloitte, KPMG, SGS, Hitachi, Oracle, Systemiq, and Kumi.

This collaboration is crucial in coalescing industry, regulators and the ecosystem around common standards for circularity and responsible sourcing, driving interoperability and adoption at scale.

Credibility and trust:

Circulor is the global leader for battery material traceability, used at scale by brands like Volvo Cars, Polestar, Volkswagen, Daimler, and BMW with a growing network of ~200 supply chain participant facilities on the platform including producers, miners, and recyclers.

Customers are effectively managing risks, making progress towards their sustainability goals and getting compliance ready. A great example of this is the world’s first Battery Passport with Volvo Cars.

Discovering the actors in supply chains and retrieving the primary data from each takes time and requires precision. As a neutral third party that gathers data digitally and securely through industrial IoT applications, Circulor reduces risks of human error or data manipulation, helping to alleviate doubt, whilst providing higher degrees of assurance to consumers, investors, and regulators.

Get started today

Third-party neutrality underpins trust, credibility and accountability - the fundamentals of supply chain transparency.

Collaborating with an experienced partner, like Circulor, is the most efficient way to prove truly responsible supply chains that meet sustainability goals and regulatory requirements, while safeguarding integrity and building trust.

Our existing battery value chain network is the largest of its kind which means new supply chain participants enjoy a fast and simple onboarding process as a portion of their supplier network will most likely be on the platform already. This expansive coverage also provides the flexibility needed to adapt to the dynamic nature of supply chains.

![Acculon RA Circulor - website image.001[44].png](/_next/image?url=https%3A%2F%2Fdecisive-wonder-fa24533282.media.strapiapp.com%2FAcculon_RA_Circulor_website_image_001_44_2720fb315d.png&w=1920&q=75)