01.11.2023

Commentary

Circulor’s Material Traceability evidences recycled content specifics, underpinning key criteria of Digital Product Passports

As manufacturers begin to actively pursue their circular economy goals and ensure they adhere to the evolving regulations, incorporating and proving rising volumes of recycled content into their products will become increasingly important.

The benefits and advantages of recycling are already well understood: conserving and securing resources, reducing costs, minimizing environmental impacts, managing corporate reputation management, meeting shifting consumer demands for more responsible products, and building greater supply chain resilience.

Central to the recycling challenge is low visibility of the material provenance, as well as purity and inherited upstream activities. Moreover, equipping manufacturers with verifiable proof of a material’s characteristics is critical in freeing them from having to rely on claims and anecdotes. By 2026, the European Union (EU) plans to prohibit general environmental claims such as "climate neutral" unless properly substantiated. This move, as a growing effort to prevent greenwashing, will also scrutinize claims about carbon offsetting and green labels without accreditation.

Claims and anecdotes are wholly insufficient in evidencing recycled content. Circulor regularly encounters scenarios in which disparities are uncovered between claimed recycled content and actual recycled content. At times, the proportion of actual recycled content is, in fact, zero. Unsubstantiated claims around recycled content also carry significant risks as many manufacturers must ensure their products meet technical standards to accurately satisfy safety and quality requirements for their customers.

When it comes to recycling, manufacturers need to know:

- What is the actual recycled content in my product?

- Where does the recycled material come from?

- What is the quality of recycled feedstock?

- What is the mix and variation percentages?

- Does it meet the technical standards for the products that I make?

- What are the associated embedded emissions of the recycled content that I buy/use?

- How do I prove that the recycled content in my products is increasing over time?

- Does the recycled content in my products enable my company to comply with market requirements and/or qualify for certain government incentives?

Manufacturers – especially those producing batteries – will be required to prove increasing volumes of recycled content in their products over time. To achieve this, they must understand who is in the supply chain, where the material is coming from and the recycled content of that material.

How Circulor evidences recycled content volumes

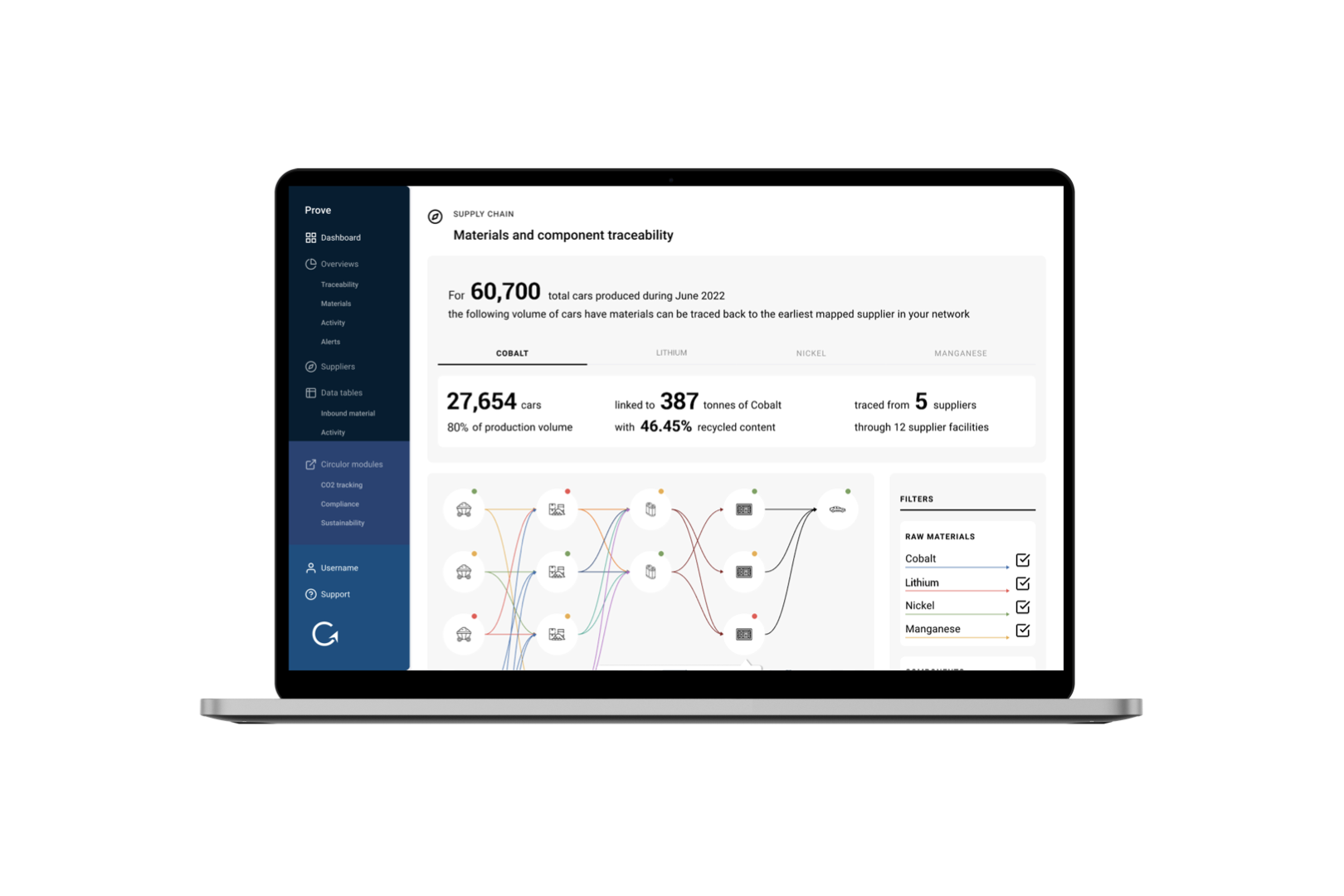

With Circulor, materials to be recycled (just like traced virgin materials) have their attributes defined as they enter the supply chain. The system creates a ‘digital twin’ of the material which then stores the relevant data about the material as it moves from one stage of production to the next and potentially through a closed loop system. This includes data generated from both production processes and logistics.

Using Circulor’s Material Traceability module, supply chain participants gain credible insights into the recycled content (%) of each material received into their facility and, each product they produce.

Recycled content (%) is collected along the length of the supply chain and attributed to the flow of materials, when materials are blended to produce an output product, Circulor apportions recycled content (%) accordingly to calculate and attribute the precise and accurate recycled content (%) to each output product.

For recyclers, amidst diverse global recycling practices, traceability helps them to prove and demonstrate to downstream customers why their processes are best in class, while also playing a critical role in establishing the authenticity, provenance and proportions of recycled materials.

A Battery Passport without traceability does not provide the necessary data for circular economy initiatives

In the U.S. (Inflation Reduction Act) and the EU (Battery Regulation and Critical Raw Materials Acts), the retention and reuse of critical materials will need proof of origin and proof that they were recycled in certain geographies.

As they are often the Economic Operators, as defined by the EU Battery Regulation, automotive original equipment manufacturers (OEMs) need to prove increasing recycled content volumes and ensure that batteries in their EVs are safely handled into repurposing and recycling.

Under the EU Battery Regulation, from August 2028, Economic Operators must provide data on the % share of recycled content of cobalt, lead, lithium or nickel in active materials that has been recovered from battery manufacturing waste (except for lead) and/or post-consumer waste, for each EV battery model, per year and per manufacturing plant.

Then from August 2033, EV batteries that contain cobalt, lead, lithium or nickel in active materials must prove they meet minimum recycled content targets of 16% cobalt, 85% lead, 6% lithium, 6% nickel. Four years later, in 2037, targets rise again to 26% cobalt, 85% lead, 12% lithium, 15% nickel.

Therefore, to meet these recycled content targets recycling capacity must increase rapidly over the next 10 years, with traceability embedded from the start to create verifiable closed loops that battery assets are handled appropriately and that their materials feed into the next generation of battery manufacturing.

These complex calculations are impossible to render accurately without the specifics provided by material traceability. Additionally, the data required to unlock the numerous advantages that recycling will bring takes time to assemble as much of it resides in the supply chain. Getting started now is a smart move for leading companies looking to anticipate and prepare for growing requirements in compliance and also unlock the myriad of opportunities that can come with building circular economies with substantiation and proof.

If you would like to learn more about Circulor’s PROVE platform and how our Material Traceability supports your recycling goals, please get in touch.

![Acculon RA Circulor - website image.001[44].png](/_next/image?url=https%3A%2F%2Fdecisive-wonder-fa24533282.media.strapiapp.com%2FAcculon_RA_Circulor_website_image_001_44_2720fb315d.png&w=1920&q=75)