21.10.2021

Press Releases

Blackstone to Implement Product Traceability from Mining to EV End User

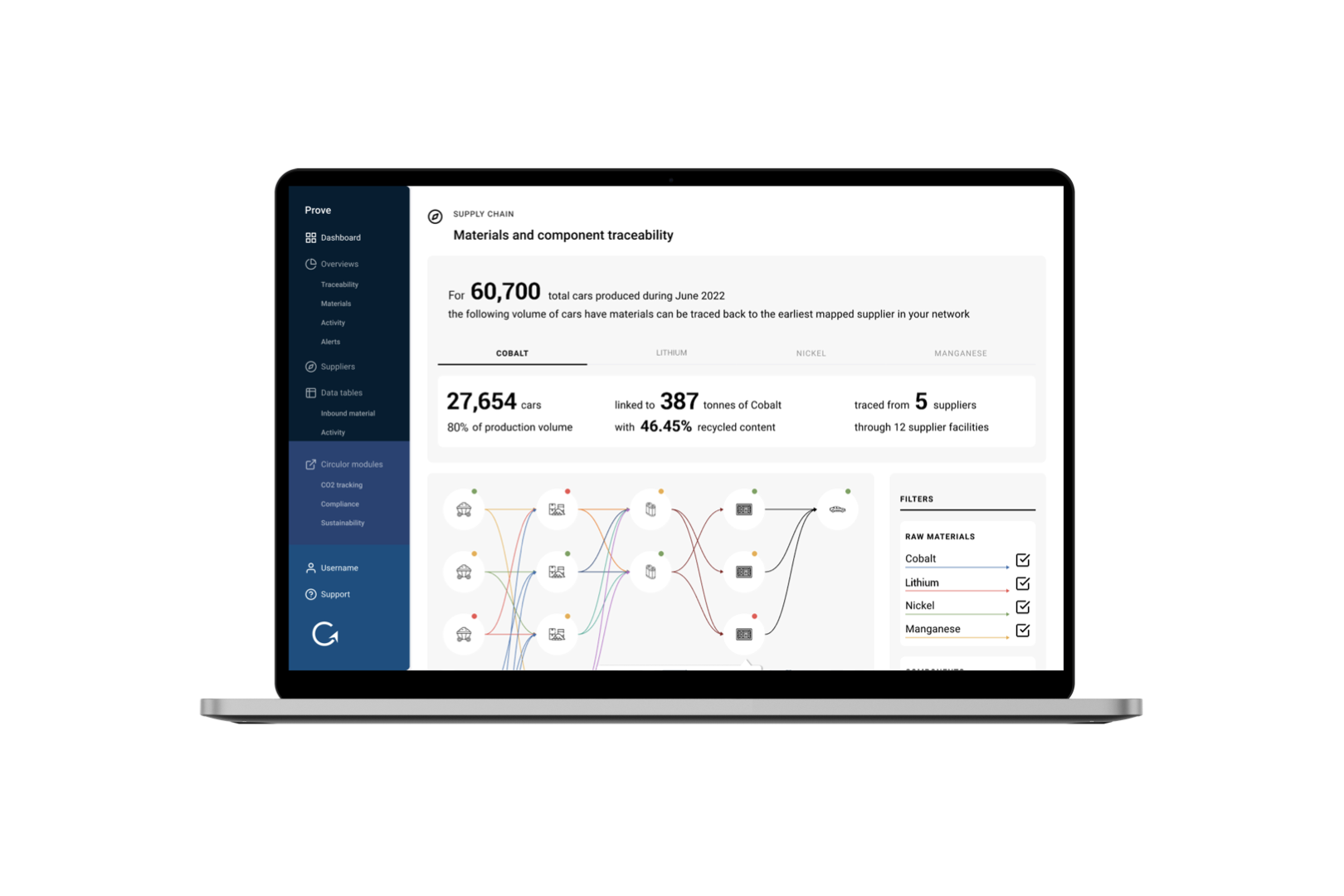

Blackstone Minerals Limited (“Blackstone” or the “Company”) is pleased to announce its collaborative partnership with Circulor Ltd (“Circulor”), the UK headquartered industry leader in supply chain traceability, to establish a full Nickel and Cathode Precursor (PCAM) traceability system, with dynamic CO₂-e (carbon dioxide equivalent) and environmental, social and governance (ESG) tracking for its Vietnam Ta Khoa Assets, a first in South-East Asia.

Globally, there is increasing awareness about the impacts associated with nickel production, as well as other critical raw materials sourced for the Lithium-ion battery industry and EV sector, with end users now demanding a level of traceability for all their products. Blackstone’s partnership with Circulor will enable the Company to demonstrate compliance with sustainability metrics from mining through to the Ta Khoa Refinery (TKR) finished product.

Blackstone is determined to be a leader in ESG innovation and the Company’s partnership with Circulor is at the cutting edge of an industry movement towards increased transparency and traceability of raw material supply chains. The end customer will ultimately demand and preferentially consume ethically and responsibility sourced nickel, which we believe the Ta Khoa Project inherently possesses. Beyond tracing supply from the Ta Khoa mine, we are pleased that our partnership with Circulor is also aligned with Trafigura, one of the largest global commodity traders and potential feedstock supplier for the Ta Khoa Refinery. Trafigura has also recently announced a collaborative partnership with Circulor and this commitment to tracking sustainability metrics is reflective of Blackstone’s expectation of all potential feedstock suppliers of the Ta Khoa Refinery.

Scott Williamson, CEO at Blackstone

Highlights

- Dynamic ESG metrics - including CO₂ intensity, biodiversity impact, water use and energy mix, will be digitised from project samples and made available for potential downstream market

- Circulor and Blackstone will work together to demonstrate a reliable chain of custody, using Traceability-as-a-Service (TaaS) technology to provide the Company with the ability to communicate the ESG “passport” of its products and operations with downstream customers

- Blackstone believes transparency and traceability of the TKR’s vertically integrated supply chain will result in the best commercial outcomes for the Company.

Yue Jin Tay, Director of Business Development at Circulor, comments: "We are very pleased to partner with Blackstone on their traceability journey from their development phase through to full operations. Building traceability into the development process of a mine and a refinery allows our customers to have traceability-by-design - ready to track the provenance, CO₂- equivalent and ESG performance of its products and raw materials from the very first shipment to their downstream customers. As Circulor expands into Asia and Australia, we are excited about the possibilities this partnership brings. With the security of supply of critical minerals gaining increasing focus, helping Blackstone provide transparency for both provenance and ESG performance enables them to become a supplier of choice in the region. This also helps them and their global customers meet a range of stakeholder requirements including the EU Battery Regulations, and their financing and investment requirements, among others."

Authorised by the Managing Director on behalf of the Board of Blackstone Minerals Limited.

![Acculon RA Circulor - website image.001[44].png](/_next/image?url=https%3A%2F%2Fdecisive-wonder-fa24533282.media.strapiapp.com%2FAcculon_RA_Circulor_website_image_001_44_2720fb315d.png&w=1920&q=75)